With video available at YouTube

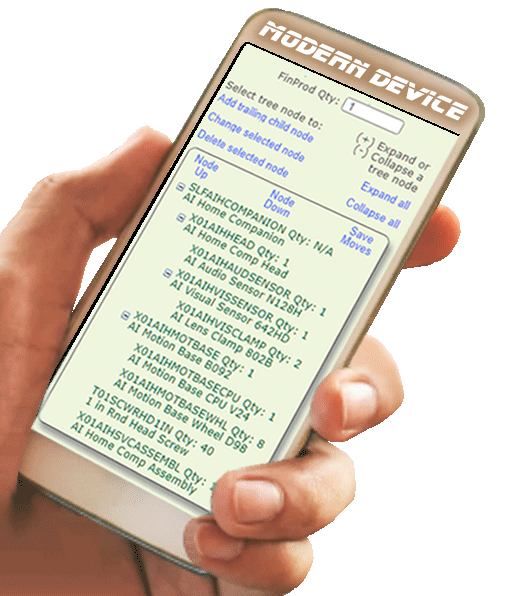

this Bill of Materials feature of our device friendly Tritex Accounting Web™

application can be located in its Codes/Inventory and Reports/Inventory sub menus,

and provides formula maintenance on a user-friendly tree-view interface, and

up to 5 quantity-extension production levels, each step including ample notes and an

optional image or diagram. It also provides the corresponding Extension Report

for the formulas, and the Raw Material Requirements report, which allows back order

filtering, selection and ordering by 'chronological / finished product / customer name',

or by any combination of the 3, thereby providing production flexibility when pressed with component

purchases, as each different ordering sequence depletes the report's raw material differently,

yielding requirement or purchasing priority changes.

The Codes/Inventory menu also includes reports for Production on Quantity Available, and

Production for Specified Quantity with the automatic quantity-transfer-to-finished-product

option available only when not running into any raw material shortages, and when there is something

to produce. Using recallable user criteria such as 4 combinations of ordering-by

'order number / product code / customer name', criteria for 'Production, Non Production or All',

and ranges for order number, entry date, customer number, customer name, order status and

product code the Projected Job Cost report details and extends item cost, labor and sales price

based on the quantity ordered, compares cost and price and provides a profit amount and estimated

gross profit percent. The report excludes raw material that belongs in a BOM formula, and

also skips unfilled and filled back orders, as the original order already reports for the group.

The Reports/Inventory menu provides the Production Forecast report, which

includes finished product quantity sold for the past 12 months, and quantity forecasted for the

current month, extends raw material shortages, and is based on previous year history for that month.

The Production on Quantity Available, Production for Specified Quantity and

Production Forecast reports end in a Pending Purchases Breakdown section.

All reports include drill down and search features, and user criteria is recalled when applicable.

Please note that we can assist with the conversion of any previous BOM formulas from other systems, as well

as the conversion of any other current or historical data.

With video available at YouTube

this Bill of Materials feature of our device friendly Tritex Accounting Web™

application can be located in its Codes/Inventory and Reports/Inventory sub menus,

and provides formula maintenance on a user-friendly tree-view interface, and

up to 5 quantity-extension production levels, each step including ample notes and an

optional image or diagram. It also provides the corresponding Extension Report

for the formulas, and the Raw Material Requirements report, which allows back order

filtering, selection and ordering by 'chronological / finished product / customer name',

or by any combination of the 3, thereby providing production flexibility when pressed with component

purchases, as each different ordering sequence depletes the report's raw material differently,

yielding requirement or purchasing priority changes.

The Codes/Inventory menu also includes reports for Production on Quantity Available, and

Production for Specified Quantity with the automatic quantity-transfer-to-finished-product

option available only when not running into any raw material shortages, and when there is something

to produce. Using recallable user criteria such as 4 combinations of ordering-by

'order number / product code / customer name', criteria for 'Production, Non Production or All',

and ranges for order number, entry date, customer number, customer name, order status and

product code the Projected Job Cost report details and extends item cost, labor and sales price

based on the quantity ordered, compares cost and price and provides a profit amount and estimated

gross profit percent. The report excludes raw material that belongs in a BOM formula, and

also skips unfilled and filled back orders, as the original order already reports for the group.

The Reports/Inventory menu provides the Production Forecast report, which

includes finished product quantity sold for the past 12 months, and quantity forecasted for the

current month, extends raw material shortages, and is based on previous year history for that month.

The Production on Quantity Available, Production for Specified Quantity and

Production Forecast reports end in a Pending Purchases Breakdown section.

All reports include drill down and search features, and user criteria is recalled when applicable.

Please note that we can assist with the conversion of any previous BOM formulas from other systems, as well

as the conversion of any other current or historical data.

|

More Details:

More Details:

|

Should you decide to track production of finished products given raw material then

this feature is easily implemented, requiring that your inventory code table flag

finished products (the default) and raw material, that the back order sub-system

be turned on in system preferences, and that certain rules concerning Unit of Measure

be followed for finished products. For instance, when a chair includes 4 casters,

and you purchase entire casters and not their separate parts then should you begin to

purchase the separate parts, and begin to build your own casters then label that as a

separate product than the original caster, and create a new chair finished product,

which new formula will address your new caster ingredient and its sub-ingredients.

The new products will prevent requirement and cost reports from mixing up and creating

unreliable results. Once the older product is no longer sold, and its report

cycles are finished the formula and finished product can then be optionally removed from

history. If the new formula has the chair, each with 4 casters, each with 1 stem

and 2 wheels, and in addition you introduce the original '4 casters per box', which

carry your cost per box and not per caster, then make sure that the new and old

casters have different product codes. Also make sure that once a product's unit

is changed after the fact ('4 per box' to '6 per box') then instead create a new

product, else the quantity on hand might become unreliable should a box be broken

for a particular sale.

The BOM feature is best used in conjunction with back order system preferences, where

a chronological back order scan would determine the current purchasing priorities,

allowing manual intervention based on availability, cost, or vendor/customer/product

preferences. Back order quantities could be broken down by Vendor, Product,

Customer, Vendor/Product, Vendor/Customer, Product/Customer, Vendor/Product/Customer,

or any order therof, allowing vendor, product and customer filters to manually address

your preferences, which would override a chronological order. Without the use of

back orders your customer filtering is lost, thus requiring manual analysis of who is

ordering what to determine preferential override through the remaining vendor and

product filters. Any filtering override would be included in report sub-headings,

so that several filter iterations could be compared previous to purchase order

maintenance. Note that the Reports Inventory menu provides a Production Forecast

report based on last year's same month quantity sold, which could prove to be

beneficial in not missing potential sales, and which 'Can Build' column provides the

maximum possible production beyond finished product quantity available.

The general BOM filtering option may provide:

-

Based on existing finished product back order quantities, or on

manually provided desired finished product quantities determine

raw material requirements for the production cycle.

Without the use of back orders you have to figure out who ordered

what, as customer filtering is not possible.

-

Given raw material available quantities determine finished product

quantities that could be currently produced. The same as above

applies here, where filtering may provide an additional advantage.

Just make sure to be fair to the other customers.

The Bill of Materials grid lists one row per finished product formula, and is based

on the 'Bill of Materials entire list', or on the 'Status 7 Back Order filter'.

The back order source is used to filter out currently unordered products, and the

entire list is used to run general maintenance of any BOM formula. When adding

a new formula off the grid's screen the Tree screen is bypassed and you are taken

directly into the maintenance screen, where the finished product and sub-product are

entered. When saving the new entry you are then taken to the tree screen, which

represents a visual interface for Bill of Materials formula maintenance. When

selecting a grid row the formula is displayed in the hierarchical tree,

representing up to 5 node levels, which can be expanded or collapsed,

which tree view greatly improves the formula maintenance interface.

Tree nodes can in turns be parent to next level children nodes, allowing

for raw material quantities to be extended through the levels, and providing

the required raw material for the intended finished product quantity.

Note that formulas may include 'overhead' raw material to cover for waste

production material. Up or Down node movement within the tree will not

work when attempting to move an item to another parent node, such as

the first and last items, in which case you need to re-enter the correction,

however, it will work when moving a parent up or down within the same grandparent,

which carries all of the children nodes with the parent, including higher levels.

Deleting a node will delete all children nodes, including higher levels, but

this step will warn the user and require confirmation. The reason to

perform these moves is to change production priority.

Please reference Help in the tree view's screen.

Following raw material purchases and finished product production the next

'Fill Back Orders' cycle would automatically scan back orders chronologically

to ship as much as it can and back order the difference, while moving the same

status 7 back order to status 3 for picking preferences, or to status 1 for

non picking preferences. Or the manual back order fill procedure could be

performed to first fill a preferential back order by changing the back order status

from 7 to 3 or 1 in sales order maintenance, removing freight amount, and

shipping as much as possible in the appropriate line items. Should

raw material be on back order as well then the probable manufacturer entity

would accept it in the fill back order process, while it would take away from

required raw material for production. Production reports are necessary

throughout the production cycle, and given filter/sort preferential discrepancies

in their sub-headers you may gauge purchasing priorities that were applied.

The Full BOM Extension Report is run from the Bill of Materials search

screen, providing the entire set of formulas by Finished Product / Raw Material.

However, if you advance to a specific finished product it will in turns provide the

BOM Extension Report for that product only. These reports group

raw material by finished product, ordering raw material per level in the order specified

during maintenance. Different level raw material could be repeated in a different

formula level and with a different extended quantity. For instance, level 1

extends a required quantity, level 2 extends the level 1 results, and so forth,

thus providing required raw material and shortages on some reports, and allowing

the user to automatically transfer inventory on-hand from raw material to finished

products on a finished product by finished product basis. The Production for

Specified Quantity Report provides the option to automatically transfer quantities

to finished product, which is available through the Tree View screen.

|